简介

The brew unit is the central component of a coffee machine. It requires regular cleaning and maintenance, in particular the seals must be replaced from time to time. Unfortunately, the brew unit is at Jura and construction-type machines of e.g. Krups, AEG not easily accessible. The removal is described here.

-

-

The instructions are suitable for nearly every model of Jura and similar ones e.g. AEG and Krups.

-

Remove the water reservoir.

-

-

-

Using an oval head bit you can screw them out. If you haven´t got one you can carefully use pliers. It is a good idea to later change the screws for normal ones.

-

Beneath both top side covers are two Torx T15 screws. Remove those. Now lift off the whole top cover. Sometimes it jams and you have to use a bit of force.

-

The side covers must be pushed backwards by about 1 cm. Sometimes this is a little bit difficult to move. If necessary, wedge a plastic opening tool into the gap between the side covers and the front panel. The rear cover can be easily removed.

-

-

-

Slide the coffee funnel up and lift it out. It often sits very tight and you have to pull hard until it becomes free.

-

It is often firmly locked in place, it loosens if you wiggle it back and forth a little. It can also be fastened with a screw.

-

-

-

-

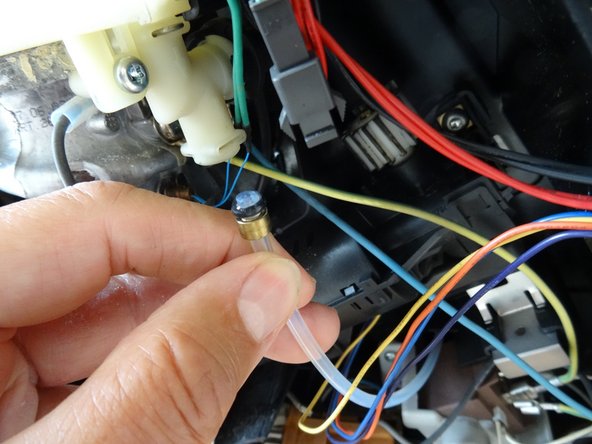

Now the brew unitis free. Tilt it to the bottom but pay attention to the pressure hose. It must be led through an opening. Then push the brew group slightly downward to lift it out of the unit.

-

For further disassembly of the brew unit use this manual JURA Brewgroup Disassembly

-

Reverse the steps to reassemble your device.

(Note: if necessary, the oval screws can also be unscrewed with combination pliers and then replaced with others)

Reverse the steps to reassemble your device.

(Note: if necessary, the oval screws can also be unscrewed with combination pliers and then replaced with others)

10等其他人完成本指南。

由衷感谢以下译者:

100%

这些译者帮助我们修补全世界! 您也想加入吗?

开始翻译 ›

5条评论

The position is not very important. The distance between the big wheel and top may be about 4 cm. My guess is, that the position of your screws is wrong. Look at the pictures in step 7: the blue one is a machine screw and must not be removed. On the left side remains one screw (yellow) beyond the blue. On the right side are two screws (red), one near of the drainage valve and one above. In the upper region of the brewing unit are two empty holes, maybe you filled them?

bonjour j’ai bien nettoyé ma jura Impressa-F50-Pumpe e75 le groupe fonctionne parfaitement à la main mais se bloque en bas et en haut pendant la mise en place de la machine , pourtant j’ai changé le moteur et l’encodeur, que peut il se passer merci pour votre réponse cordialement

Dans ce cas, je devinerais l'encodeur. Mais s'il a déjà été échangé, est-ce peut-être l'électronique? C'est dommage.

VauWeh -